Automatic Rubber Calender Line Rubber Sheet Making Calendering Machine

Basic Info.

| Model NO. | HK |

| Gap | Adjustment |

| Gearbox | Hard Gear Reducer |

| Applicable Industries | Manufacturing Plant |

| Product Name | Automatic Rubber Sheeting / Calender Machine |

| Application | Rubber Sheet Process |

| Motor | AC |

| Certification | ISO9001:2008/CE |

| Electric Part | Chnt ,Omron |

| Advantage | Low Noise, High Efficiency |

| Calender of Rubber Mat Machine | High Precision |

| Machine Type | Fully Automatically |

| Color | Customer Demand |

| Voltage | as Customers Requirement |

| Control | Automatic Control |

| Key Selling Points | High-Accuracy |

| Transport Package | Standard Export Packing Way |

| Specification | Customized |

| Trademark | Evertech |

| Origin | China |

| HS Code | 847780000 |

| Production Capacity | 30 Set/Sets Per Month |

Product Description

Automatic Rubber calender line Rubber Sheet making calendering machine Product Description1.Rubber sheet Calendering Application:Rubberizing and fractioning of textile material, rubberizing of wirecord fabric, sheet, and counter plate(embossed) of rubber material, separation of fabric and film, as well as joint of multi-layer laminate film.2.Rubber sheet Calendering General design:It mainly contains roller, rack, backplane, adjustment, device, transmission system, roller temperature control device, security device, lubricating device, etc.3.Rubber sheet Calendering Features:The roller is made of chilled cast iron alloys, whose work surface has high hardness, wear-resistent and durable life. Steam, cooling water, and heat-conducting oil can pass into the rollers cavity, so that the working temperature can be adjusted in order to meet the technical requirements.Roll spacing can be adjusted both by manual or electric mode.Roller bearings lubricating can adopt drier oil or dilute oil.

Product ParametersRubber sheet Calendering1.Higher Productivity2.Better processing of rubber3.Minimal manual interference4.Higher quality products

| Model & Parameter | XY3I 630 | XY-3I 1120 | XY3I 1400 | XY3I 1500 | XY3I 1730 | XY3I2130 | |

| XY3L 631 | |||||||

| XY-3L1120 | |||||||

| Roll dia | mm | 230 | 400 | ||||

| Roll working length | mm | 630 | 1400 | ||||

| Roll ratio | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | |

| 1:1.38:1.38 | 0.73:1:1 | 1:1.38:1.38 | |||||

| 1:1.42:1 | 1:1.38:1 | 1:1.38:1 | 1:1.5:1 | ||||

| Middle -roll liner speed | r/min | 0.8-8 | 3-21.06 | 3-26.39 | 2.62-26.2 | 5.5-54 | 8-50 |

| Adjusting nip range | mm | 0-7 | 0-10 | 0-10 | 0-6 | 0-20 | 0-20 |

| Min.Calendering product | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.15 | 0.15 |

| thickness | |||||||

| Motor Power | kw | 100-500 | 500- | 1200 | 1400 | 1400 | 1900 |

| Overall Dimensions | mm | 3168 | 5550 | 6500 | 7420 | 7010 | 7650 |

| mm | 890 | 1640 | 1500 | 2200 | 3950 | 4560 | |

| mm | 1830 | 2120 | 2440 | 2900 | 3730 | 4080 | |

| About weight | t | 2.6 | 11 | 22 | 26 | 52 | 67 |

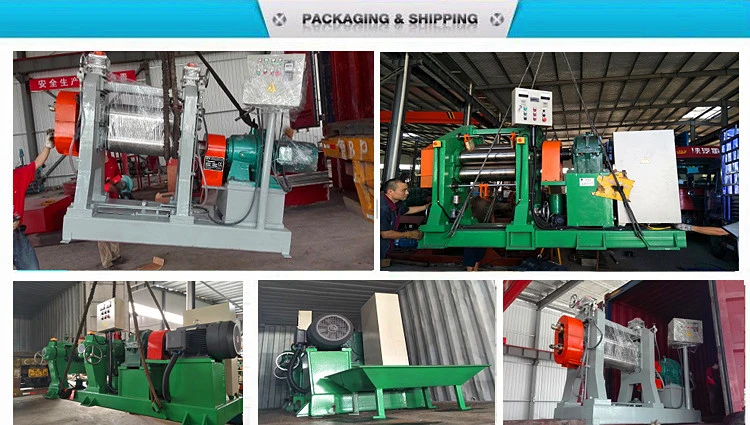

Packaging & Shipping

Our machine has been widely exported to USA , UK ,Russian , South Korea , Japanese , India , Poland , Spanish ,Mexico and many other areas .

Qingdao Evertech Industry Co., Ltd. is a professional pressure vessel designer, manufacturer and exporter. We have manufacturing licenses for ASME U, ASME U2,NB,PED, D1, D2 and A2 pressure vessels. Composed of more than 20 senior experts and professional engineers, the research and development team, with more than 20 years of professional experience, is committed to product design, development and program optimization, and can provide high-quality solutions according to users' requirements in different operating conditions. Company has cover an area of 70000 manufacturing base and 15000 modern manufacturing plants, can provide customers both at home and abroad with composite autoclave, high pressure autoclave, high pressure reactor, AAC autoclave, deaerator, pouring tank pressure vessel products such as more than 800 sets, pressure vessel head more than 20000 sets high quality products and services, won widespread praise.

Our Service

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3)Order process:

We offer below business term:

Accepted Delivery Terms | FOB, CFR, CIF, EXW, DDP |

Accepted Payment Currency | USD, EUR, HKD, CNY |

Accepted Payment Type | T/T, L/C, Credit Card, PayPal, Western Union, Cash, Escrow |

Nearest Port | Shanghai, Qingdao, Tianjing or rquired |

4)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

5)Installation and after sale service:

Defines installing those products in the field and providing after-sales support.