Category

Two Roll Rubber Roller Mixer Machine Open Mixing Mill for Laboratory

Overview Two Roll Rubber Roller Mixer Machine Open Mixing Mill for Laboratory Product Parameters Product Description Fea

Overview

Product Parameters

Product Description

Feature1. The core technology and main components are from Taiwan;

2. The electronic control part adopts imported electrical components, which are convenient to operate and stable in performance;

3. The distance adjustment method is optional for manual distance adjustment/electric distance adjustment;

4. The overall bottom plate is easy to install, and the transmission mode is single shaft output to ensure large torque. Imported bearings reduce friction force to ensure power saving, low noise, and uniform and controllable rubber thickness;

5. The roller is made of vanadium titanium alloy chilled cast iron, with a hard and durable surface The finishing of the inner cavity of the roller ensures rapid and uniform cooling of the roller body; 6. The roller bearing is a rolling bearing, and the lubrication method of the roller bearing is grease;

7. The machine is equipped with an emergency brake. When an emergency occurs, there are emergency switches at the four corners to facilitate multi position braking and quick stop of the machine. Pull the emergency switch to immediately brake the machine, ensuring safety and reliability;

8. The transmission system device adopts a hard tooth surface reducer with compact structure, high transmission efficiency, low noise, and long service life;

9. The machine is equipped with an overload protection device to protect main parts from damage due to overload. Company Profile

Xiamen Webron is a national high-tech enterprise, a star enterprise in Fujian Province, and a well-known innovative technology research and development enterprise. It was registered in the Cross-Strait Equity Trading Center in 2021, with the enterprise code of 867467; The headquarters is located in the Tsinghua Strait Research Institute. It is a 3A credit enterprise in China, a member unit of the Mechanical Mold Branch of the China Rubber Industry Association, a key recommended private enterprise in Fujian Province, and a member unit of the Fujian Plastic Industry Association; Signed contracts with 15 professors in the fields of polymer, metal, and ceramics, has industry-university-research cooperation with multiple universities, and has joint laboratories with universities; It is a metal ceramic rubber plastic machinery technology enterprise specializing in research and development, design, manufacturing and sales, and after-sales maintenance services. Company Vision: Let China's mixing technology synchronize with the world. Serving new material enterprises such as polymer materials, graphene materials, advanced ceramics, and powder metallurgy, our core products include torque rheometers, rubber internal mixers, metal internal mixers, ceramic internal mixers, internal mixing and granulation integrated machines, open mills, twin screw extruders, and plate vulcanizers.

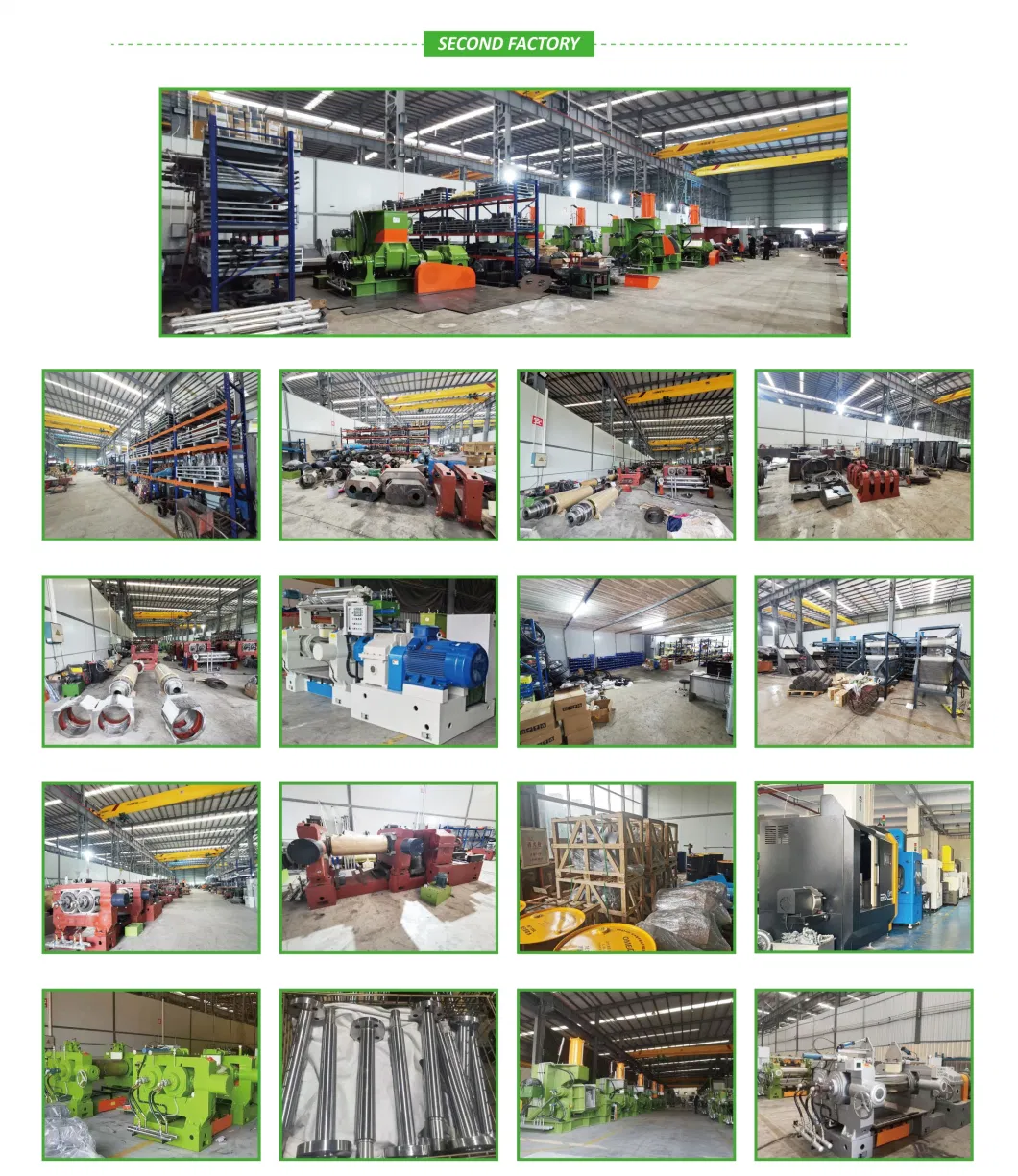

The company has successively passed the certification of ISO 9001, intellectual property management system, and high-tech products. It has strong production capacity and advanced technological processing equipment, such as 10 five-axis CNC machining centers, 4 CNC lathes, 5 slow moving wire and other imported processing equipment. The company has independent laboratories, and various materials and experimental equipment are provided to customers for visiting/testing formulas/proofing. The professional R&D and design team can meet the special non-standard requirements of customers and customize the model, which has been recognized and praised by the majority of customers.

Since its establishment, Webron has worked hard, innovated, and made progress. The company promises to produce high-quality products for you with specialized technology, and to create higher value for you with high-tech achievements! Xiamen Webron Technology Co., Ltd. is willing to work with you to create a brilliant future!

Q1. How to choose the most suitable Mechanical Equipment ?

A1:Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

Q2. What's the delivery term?

A2:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q3. Do you accept customization service?

A3:Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q4. Can we visit your factory before order?

A4:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q5. How about your warranty?

A5:1. Provide on-site installation guidance;

2. Responsible for on-site commissioning and trial run of the supplied equipment until it passes the acceptance;

3. Responsible for on-site operation and maintenance training for Party A's personnel;

4. The unit is warranted free of charge for one year under correct use, and the supply of spare parts is guaranteed for a long time;

5. Provide long-term free technical service consultation;

6. Within and outside the warranty period, the supplier shall provide clear solutions within 3 hours after receiving the buyer's equipment failure notificatio

Basic Info.

| Model NO. | 6inch |

| Application | Rubber Products |

| Mechanical Weight | 475kg |

| Key | Rubber Machinery |

| Name | Open Mixing Mill |

| Transport Package | Standard Export Wooden Box |

| Specification | customized |

| Origin | China |

| Production Capacity | 500PCS/Month |

Product Description

Two Roll Rubber Roller Mixer Machine Open Mixing Mill for LaboratoryProduct Parameters

| Name | Small Open Mixing Mill |

| Temperature range | Normal temperature - 300 ºC |

| Temperature controller | LED digital display, key setting input |

| Heating method | Electric heating tube |

| Revolution ratio | 1:1.27 |

| Speed | Constant speed/speed regulation (optional) |

| Roller size | 120*L320mm/150*L320mm(optional) |

| Roller spacing | 0.05-8mm Adjustable |

| Safety protection | Safety devices such as pull rod emergency stop and knee top reverse |

| Volume | 990*390*1150(W*D*H)mm |

| Source | AC380V,13A,Three phase five wire |

| Weight | 475kg |

Feature1. The core technology and main components are from Taiwan;

2. The electronic control part adopts imported electrical components, which are convenient to operate and stable in performance;

3. The distance adjustment method is optional for manual distance adjustment/electric distance adjustment;

4. The overall bottom plate is easy to install, and the transmission mode is single shaft output to ensure large torque. Imported bearings reduce friction force to ensure power saving, low noise, and uniform and controllable rubber thickness;

5. The roller is made of vanadium titanium alloy chilled cast iron, with a hard and durable surface The finishing of the inner cavity of the roller ensures rapid and uniform cooling of the roller body; 6. The roller bearing is a rolling bearing, and the lubrication method of the roller bearing is grease;

7. The machine is equipped with an emergency brake. When an emergency occurs, there are emergency switches at the four corners to facilitate multi position braking and quick stop of the machine. Pull the emergency switch to immediately brake the machine, ensuring safety and reliability;

8. The transmission system device adopts a hard tooth surface reducer with compact structure, high transmission efficiency, low noise, and long service life;

9. The machine is equipped with an overload protection device to protect main parts from damage due to overload. Company Profile

Xiamen Webron is a national high-tech enterprise, a star enterprise in Fujian Province, and a well-known innovative technology research and development enterprise. It was registered in the Cross-Strait Equity Trading Center in 2021, with the enterprise code of 867467; The headquarters is located in the Tsinghua Strait Research Institute. It is a 3A credit enterprise in China, a member unit of the Mechanical Mold Branch of the China Rubber Industry Association, a key recommended private enterprise in Fujian Province, and a member unit of the Fujian Plastic Industry Association; Signed contracts with 15 professors in the fields of polymer, metal, and ceramics, has industry-university-research cooperation with multiple universities, and has joint laboratories with universities; It is a metal ceramic rubber plastic machinery technology enterprise specializing in research and development, design, manufacturing and sales, and after-sales maintenance services. Company Vision: Let China's mixing technology synchronize with the world. Serving new material enterprises such as polymer materials, graphene materials, advanced ceramics, and powder metallurgy, our core products include torque rheometers, rubber internal mixers, metal internal mixers, ceramic internal mixers, internal mixing and granulation integrated machines, open mills, twin screw extruders, and plate vulcanizers.

The company has successively passed the certification of ISO 9001, intellectual property management system, and high-tech products. It has strong production capacity and advanced technological processing equipment, such as 10 five-axis CNC machining centers, 4 CNC lathes, 5 slow moving wire and other imported processing equipment. The company has independent laboratories, and various materials and experimental equipment are provided to customers for visiting/testing formulas/proofing. The professional R&D and design team can meet the special non-standard requirements of customers and customize the model, which has been recognized and praised by the majority of customers.

Since its establishment, Webron has worked hard, innovated, and made progress. The company promises to produce high-quality products for you with specialized technology, and to create higher value for you with high-tech achievements! Xiamen Webron Technology Co., Ltd. is willing to work with you to create a brilliant future!

Q1. How to choose the most suitable Mechanical Equipment ?

A1:Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

Q2. What's the delivery term?

A2:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q3. Do you accept customization service?

A3:Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q4. Can we visit your factory before order?

A4:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q5. How about your warranty?

A5:1. Provide on-site installation guidance;

2. Responsible for on-site commissioning and trial run of the supplied equipment until it passes the acceptance;

3. Responsible for on-site operation and maintenance training for Party A's personnel;

4. The unit is warranted free of charge for one year under correct use, and the supply of spare parts is guaranteed for a long time;

5. Provide long-term free technical service consultation;

6. Within and outside the warranty period, the supplier shall provide clear solutions within 3 hours after receiving the buyer's equipment failure notificatio