Customized L

Basic Info.

| Material Processed | PVC |

| Roller | Four |

| Roller Structure | Cavity Type |

| Roller Orientation | L-Type |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| Calendering Product Thickness | 0.05-0.5mm |

| Max. Film Width | 2200 mm |

| Applicable Industries | Manufacturing Plant |

| Warranty of Core Components | 1 Year |

| Motor Power(Kw) | 320 |

| Machine Condition | New |

| Machine Size | 30" X 118" |

| Calender Machine Type | 4-Roll, 5-Roll, 6-Roll |

| Marketing Type | Hot Product 2022 |

| Weight | 60000kg |

| Video Outgoing-Inspection | Provided |

| Automatic Grade | Automatic |

| Key Selling Points | Wide Application |

| Machinery Test Report | Provided |

| Name | PVC Soft Film Calender Machine |

| Transport Package | Wooden Case |

| Trademark | Sinotech |

| Origin | China |

| Production Capacity | 12m/Min |

Packaging & Delivery

Package Size 300.00cm * 1180.00cm * 1200.00cm Package Gross Weight 60000.000kgProduct Description

Product Description

Calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. MaterialPVC, ABS and PS constitute the majority of calendered thermoplastics, although some grades of polyethylene and polypropylene are also used.Facts of Calendering in Textile*Provides highly lustrous appearance on the fabric surface.*Provides smooth, glossy and silky touch to the fabric.*Increases fabric cover factor*Compress fabric and reduce thickness*Causes a closing to-gather of the threads by flattening them & thus tending to fill up the inter stiches between warp and weft.*Reduce air permeability by changing its porosity*Increase opacity of fabric*Reduce yarn slippage*Flattens slubs*Consolidation of non-wovenAdvantages of CalenderingThe calender is very good at handling polymer that are heat sensitive as it causes very little thermal degradation. It is good at mixing polymers that contain high amount of solid additives that don't get blended or fluxed in very well. Due to this calender is produce a large amount of melt than extrusion.

Final Product

Detailed Photos

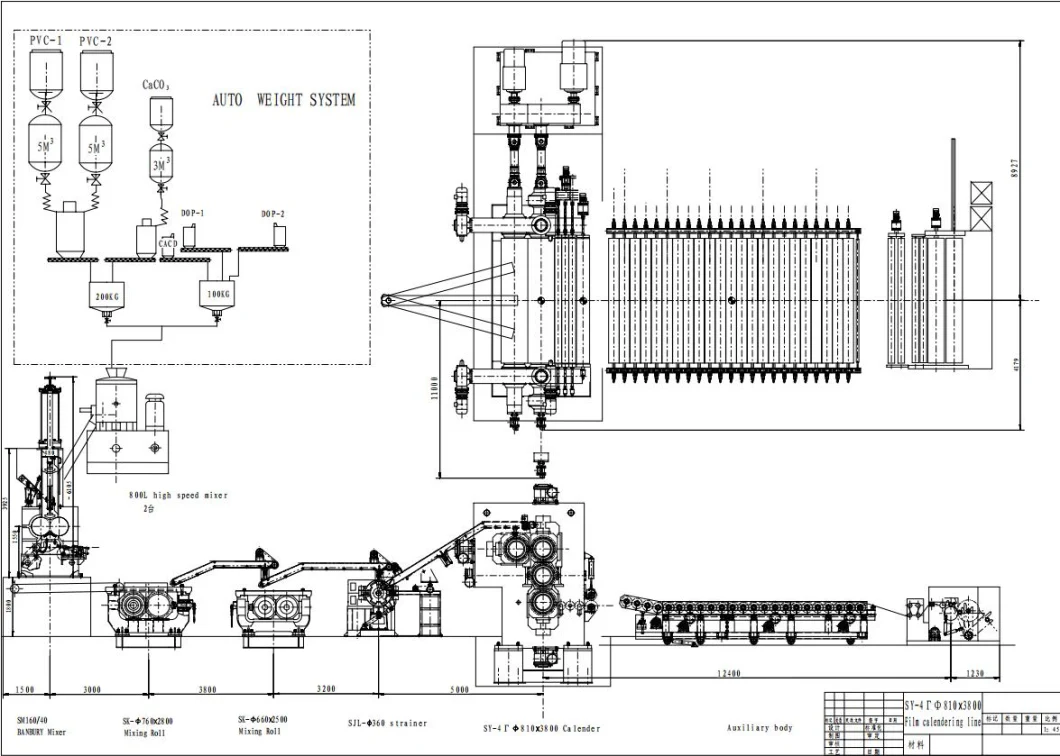

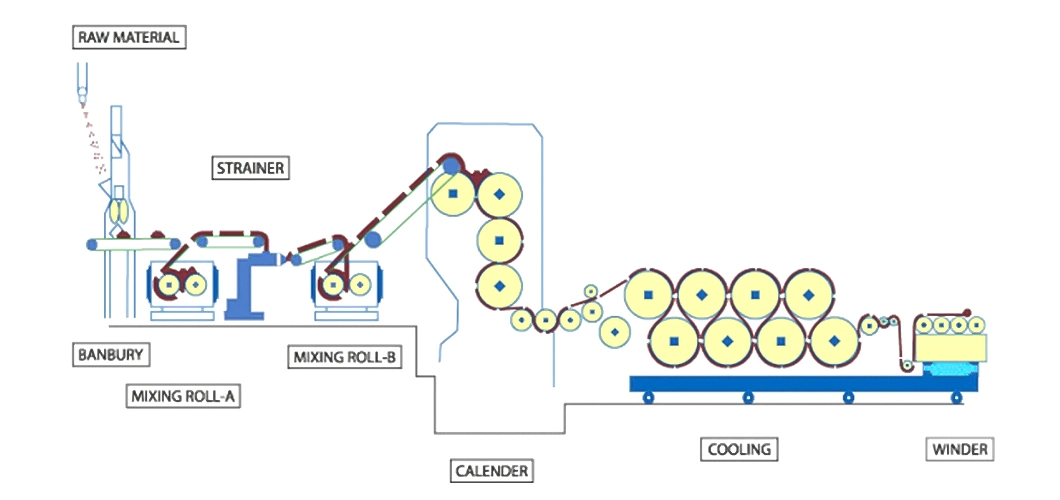

01 Calender Line for PVC Colored Film/ Embossed Film/ Transparent Film

Machine Size: 24" x 80" , 26" x 90", 26" x 100", 28" x 110", 30" x 118" Calender Machine: 4-Roll, 5-Roll, 6-RollMax. Film Width: 2200 mmGeneral Layout: Materail dosing system - Super mixer - Cooling mixer - Planetary extruder - Mixing roll - Straining extruder - Calender machine - Post of calender - Surface winderFeatures1.The rollers are drillled roll with hot grinded, single motor single transmission with a stable and adjustment speed work. The machine use roller bearing which can bear high temperature. Sealing type is labyrinth.2.The film can infinite extend, with a high work speed, high produce capacity, good quality and uniform thickness.3.The main machine has roll crossing, preloading and anti-ending device, the nip adjustment speed can be adjust, the electric has PLC control.

Calender line for PVC transparent film include PVC normal clear film line and PVC super clear film line

02 Calender Line for Artificial Leather

Artificial Leather by calender process with high output, stable quality, durable, scratch-resistant and flame resistantMachine Size: Φ610mm x 1830mmL, Φ610mm x 2030mmL,Calender Machine: 4-Roll Max. Film Width: 1540 mmGeneral Layout: Materail dosing system - Super mixer - Intensive mixer - Mixing roll #A - Mixing roll #B - Straining extruder - Calender machine - Post of calender - Central winder

03 Calender Line for PVC Flooring Film

Calender line for PVC flexible banner film include calender line for ware layer and printing layer of resilient flooring, base sheet of multilayered flooring, base sheet of LVT flooring and so ona. Calender line for ware layer and printing layer of resilient flooringMachine Size: Φ760mm x 2800mmL, Φ610mm x 2030mmL,Calender Machine: 4-Roll, 5-RollMax. Film Width: 2000mm, 1540 mmGeneral Layout: Materail dosing system - Super mixer - Cooling mixer - Planetary extruder- Mixing roll - Straining extruder - Calender machine - Post of calender - Surface winder/Central winderb. Calender line for base sheet of multilayered flooringMachine Size: Φ760mm x 2800mmLCalender Machine: 4-Roll Max. Film Width: 2000 mmGeneral Layout: Materail dosing system - Super mixer - Intensive mixer - Mixing roll #A - Mixing roll #B - Straining extruder - Calender machine - Post of calender - Surface winder/Central winder

c. Calender line for base sheet of LVT Machine Size: Φ610mm x 2030mmL,Calender Machine: 3-Roll Max. Film Width: 1540 mmGeneral Layout: Materail dosing system - Super mixer - Intensive mixer - Mixing roll #A- Mixing roll #B - Calender machine - Post of calender - Slicer

04 Calender Line for PVC Flexible Banner Film

Calender line for PVC flexible banner film include calender line for PVC frontlit banner, PVC backlit banner and PVC blockout banner, PVC inflatable film and so onMachine Size: Φ860mm x 4250mmL, Φ860mm x 4250mmL stretch to 6500mm, Φ1350mm x 7200mmLCalender Machine: 4-Roll Max. Film Width: 3200 mmGeneral Layout: Materail dosing system - Super mixer - Intensive mixer - Mixing roll #A - Mixing roll #B - Straining extruder - Calender machine - Post of calender - Surface winder

Process of Production

Company Profile

Certifications

Packaging & Shipping

FAQ

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.